![Photo [puamelia] CC-BY-SA](https://archistry.com/wp-content/uploads/2014/09/sushi_puamelia-1024x512.jpg)

That’s what I heard tonight when I rang up one of my regular, “no brainer” restaurants because the last thing anyone in the house wanted to do this evening was cook.

I order something from them at least once a week, normally lunch, and, to be fair, they’re not really a sushi place. They’re really a fast food Thai place that remodeled and expanded in February to offer sushi along with the regular and locally interpreted Thai dishes.

The sushi is basic: nigiri, maki rolls, California rolls, hand rolls and sashimi made from veggies, salmon, tuna, shirmp and crabstick.

About 50% of the time, I get a spicy tuna maki roll and some salmon and tuna nigiri as a starter to compliment whatever else I’m ordering. As I said, it’s not a sushi place. If I want proper sushi, there are a couple of outstanding restaurants here in Cape Town, but that’s a different story.

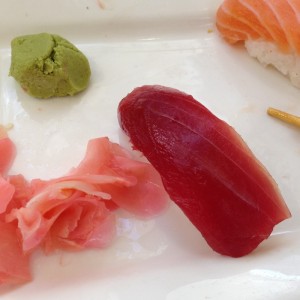

An important point to this story is that generally, the tuna we get in Cape Town looks like the small picture on the right. The pieces are large, and the color is a deep ruby red. We’re normally quite lucky.

An important point to this story is that generally, the tuna we get in Cape Town looks like the small picture on the right. The pieces are large, and the color is a deep ruby red. We’re normally quite lucky.

That’s why, even in the cheap, we-don’t-really-do-sushi places, I’ll still order tuna nigiri.

Except tonight…or last night…or, actually, every night for over the last week!

What’s wrong with this picture (besides having to order spring rolls instead)?

Still don’t see it?

What we have here, ladies and gentlemen, is nothing short of a failure in execution

Let’s look at this another way.

Around January, the restaurant (it’s actually a franchise with stores all over South Africa) closed a busy retail location for about 2 weeks to renovate and remodel the restaurant so they could sell sushi from this location. I’m not sure what their daily turnover is at this location, but it’s pretty busy, and they do lots of take-away.

In reality, the closure lasted closer to 6 weeks, so that’s almost a month of additional lost revenue.

Now, in September, they don’t have tuna…for over a week.

I asked the manager how many times have people been unable to order tuna in that time, and the answer was: “a lot.”

Then, I asked what had happened.

Apparently, they get the tuna and salmon from the same supplier. However, that supplier wasn’t able to stock tuna for some reason. They tried another wholesale/retail store 2 blocks away and another wholesaler, but neither of them could supply tuna either.

And remember, they’re not really a sushi place. They just have the basics, so if you want something fish-like, you can only get salmon, tuna, shrimp and crabstick. That means that 25% of their selection, let alone how much of their normal sushi sales on a given day, was unavailable. Yes, folks: I said 25%!

Of course, other restaurants serving sushi had tuna during this time. I checked.

Analyzing the impact

If you still think this story is about sushi, you’re wrong.

This sort of thing happens to all of us, all the time. It doesn’t matter if we’re buying groceries, and what we want to buy is out of stock for nearly a month; or if someone other than Apple doesn’t ensure they have enough stock available for a product launch to keep up with demand, and by the time you get there, you’re turned away empty handed.

[NOTE: We all know Apple does it on purpose to actually increase the scarcity and reputation of their brand. It’s no accident.]

Most of the time, we just don’t notice it and move on, but this time, we’re going to take a closer look.

What are some of the strategic objectives of the restaurant?

If you’ve been reading for a while, you might recognize some of these themes:

- Build and maintain a reputation for good quality Thai food that’s inexpensive and prepared quickly so you can either eat in or take home

- Deliver fast and efficient customer service

- Provide a core menu of expected Thai “favorite” dishes

- Cater to the somewhat eclectic South African palette by offering a variety of “Thai-style” or “quasi-Asian” dishes and accompaniments

- Provide a reasonable level of consistency in taste and spice levels, regardless of which chef is cooking

- Grow and maintain our customer base to show increased revenue and solid, bottom-line growth

- Minimize costs wherever possible while still maintaining the quality of our food

We all know that reputation sits at the top of the priority scale, and it’s a function of how well you execute and deliver many of the other objectives. Get the reputation wrong, lose customers, and you’ll likely end up cutting corners and eroding your reputation even further.

Having a well-maintained reputation gives you the “forgiveness factor” we discussed in a previous post. It means that your customers know that occasional mistakes happen, and those mistakes don’t represent how things normally work.

For me, because I go in there all the time and the manager and several of the staff know me by sight and name, my own personal forgiveness factor is pretty high. It’s much higher than if I’d only gone occasionally, or it was my first time in the store.

However, the unavailability of a core ingredient to a new line of business for over a week is a pretty serious issue—even with your loyal customers.

Do you remember what is the number one cause of strategy implementation failure? What’s the biggest cause of falling into the Strategy Gap?

Inadequate or unavailable resources.

And here, on a Friday evening – peak restaurant hours – what do we see? Unavailable resources. No tuna. One quarter of the ingredients required for a new business expansion strategy are not available—for over a week.

Keeping the fish stocked

How do we fix it?

First, we need to understand the the core capabilities implied by our business objectives. That means analyzing them to create SABSA® business attributes so that we have a set of assets that are truly important to the business.

A very first pass might give us some of the following capabilities or attributes:

- Reputable

- Quality

- Inexpensive

- Convenient (via “eat in or take home”)

- Available (via “prepared quickly” and “fast customer service”)

- Localized (from the South African versions of Thai dishes and the “quasi-Asian” menu items)

- Consistent

- Profitable

- Cost-controlled

In a proper set of SABSA attributes, each one of these would also have a definition so that we wouldn’t have any question exactly what we meant. Each attribute would also have plausible and direct traceability to the original business objective or requirement from which it was derived. However, what we have is good enough for now.

If these capabilities represent the true assets of our restaurant – what the business truly cares about – then if we’re going to successfully deliver our strategy, we must assess the risks and opportunities for each of these intangible assets. We can’t just assess risks to “the strategy” or the individual business objectives.

Why?

Because if we don’t manage the uncertainty in our ability to deliver these, we won’t be able to determine if we can successfully implement our strategy. Another very important reason is that each attribute can apply to different parts of the business or elements of delivering the strategy. If we don’t have a way to apply them where they really are generated or delivered – including being able to localize and aggregate their meanings and performance – then we’ll be leaving very serious gaps in our organization’s overall risk profile.

Let’s use our attributes and focus on our missing tuna. Which of these attributes might be relevant to making sure we have tuna to serve to our customers?

How about:

- Available

- Quality

- Consistent

- Cost-controlled

Why did I pick these?

First, the key issue here is that the tuna must be available when we need it, otherwise no sashimi, nigiri, maki or California rolls for you, mister. The risk (or level of uncertainty) for the availability of our tuna is that either a) we simply won’t have any, or b) we’ll have a lot more than we expected. That’s the difference between downside and upside risk. Both are important.

If we don’t have any, it might be because of a few different causes, with varying degrees of separation from us and the swimming fish:

- Our supplier can’t get it

- The fishermen are on strike

- The tuna are gone from the normal fishing grounds

- The tuna are sick and can’t be eaten

- The government has banned the fishing of tuna

- etc.

Again, I’m not trying to be pedantic or exhaustive here. We’re just illustrating the process.

We must ensure that the tuna we serve in our restaurant meet our own quality standards so that it is consistent with what our customers expect to be served. At the same time, we must ensure that we get the best price/quality ratio so that we can assure our tuna procurement is cost-controlled so we don’t blow our budget and impact our profitable attribute via systemic risk interactions.

It’s important to understand that each one of these attributes also has a measure and a performance target that we use to access whether we are delivering those capabilities to the business within our overall risk appetite. In SABSA-speak, that’s what makes it an attributes profile.

Our requirements for our tuna supplier are essentially our performance targets for each of those four attributes, e.g. we need an availability of 20kg of tuna/day rated at a quality standard of Grade-A from the external fish authority and passing an internal check to ensure our tuna is of consistent freshness, temperature and color, all of which needs to be delivered at R423/kg ($17/lb).

The astute reader is also bound to notice that the interactions between these 4 simple attributes can also be quite complex, but we’ll leave that aside for now as well.

Our main concern is: where’s my bloody fish???

Given the easiest threat to manage for the availability of our tuna is our supplier, it would be prudent to ensure that you did some due diligence on fishmonger candidates to ensure that there was sufficient diversity of stock origin so that if you selected a primary and secondary supplier, the risk that both were likely to be impacted by the same environmental threat was within your risk appetite, across all of the appropriate attributes you deemed relevant in this scenario.

Of course, the short version is: how confident are you that if Supplier A doesn’t have fish, Supplier B won’t be impacted by the same problems? Are you willing to bet the business on this level of confidence? Is it sufficient to meet all of your other, related objectives?

In other words: do you feel secure you will be able to serve your customers?

The root of execution failure

In this case, whoever owned the risk to the availability of the tuna made the wrong call. They didn’t deploy the right controls to manage the uncertainty around the availability of their tuna. They apparently only had one regular supplier selected, and were trying to scramble at the last minute to try and find someone – anyone – who could meet their demand (after the risk to their tuna availability passed their risk appetite and became a “high risk”).

The knock-on impacts to the other attributes might be that if they’d found another supplier, they may have struggled to maintain the performance targets for the cost-controlled, quality and consistent attributes. The supplier might have realized they were desperate, so he would’ve tried to charge more, and all the Grade-A, super fresh and ruby colored tuna was likely already sold to other customers.

There were also systemic impacts on the overall reputable attribute.

First, rather than proactively state there was no tuna, they waited for the customers to ask it and discover the problem. This undermines customer confidence and trust, both of which are components of the overall organizational reputation.

Second, should they have managed to source alternative tuna that didn’t meet the established targets for the remaining attributes, serving lesser quality and inconsistent tuna to customers also has a negative reputational impact—however fleeting it might be.

The situation also serves to highlight the systemic interactions between the risks to attributes associated with a very specific resource required to deliver the strategy impacting the reputation of the restaurant. There is no applicable way to associate reputation specifically with the tuna. The reputation is a function of ensuring the risks to the tuna are managed.

All of these failures to ensure the performance targets of the individual, localized strategy implementation details – e.g. tuna as a resource, the procurement process and fishmogers as the supply chain – resulted in an overall failure to execute the business strategy and deliver the original objectives.

This story, and countless other examples we all see in our lives every day, is why we firmly and resolutely believe that successful strategy execution is successful risk management. It is impossible to have one without the other.

Now, you have a new way of looking at the everyday issues of your own organization to try and find ways to see the real risks to successfully implementing your strategy. You understand that your strategy is dependent on the delivery of organizational capabilities—not in the abstract, but to specific, measurable levels of performance. And you also see how this approach can allow you to predict and manage otherwise invisible systemic risk interactions that could blindside you and derail your strategy.

Congratulations. You’re now well ahead of the vast majority of people out there.

If you want to know more about how to ensure you successfully implement your business strategy or would like a more in-depth understanding of the process we described above to see how it can work for you, please fill in the form below or give us a call. We’re ready to get you started today.

Sushi, anyone?